Stainless Steel 304

Have excellent low temperature properties and respond well to hardening by cold working. 304 stainless steel grades have good welding characteristics and post weld annealing is not normally required to restore performance.

Description:

- Food processing equipment.

- Heat exchangers.

- Architectural trim and molding.

- Woven or welded screens for mining.

- Automotive and aerospace structural use.

- Nuts, bolts, screws, and other fasteners in the marine environment and Dyeing industry.

Stainless Steel 316L

Alloy 316/316L is molybdenum-bearing austenitic stainless steel. The higher nickel and molybdenum content in this grade allows it to demonstrate better overall corrosion resistant properties than 304, especially with regard to pitting and crevice corrosion in chloride environments. In addition, Alloy 316/ 316L provides excellent elevated temperature tensile, creep and stress-rupture strengths, as well as outstanding formability and weldability. 316L is the lower carbon version of 316 and is immune from sensitization; therefore, it is very frequently used in heavy gauge welded components.

- Used in structural and mechanical parts.

- Hydraulic cylinder, water transportation, piling, oil and gas etc.

Application:

- Food preparation equipment.

- Chemical processing, equipment, Laboratory benches and equipment.

- Pharmaceutical and textile industries.

- Evaporators and tanks, Rubber, plastics, pulp & paper machinery and Boat fittings.

- Value and pump trim.

- Threaded fasteners.

Specification:

- Quality : AISI304/304L and AISI316/316L

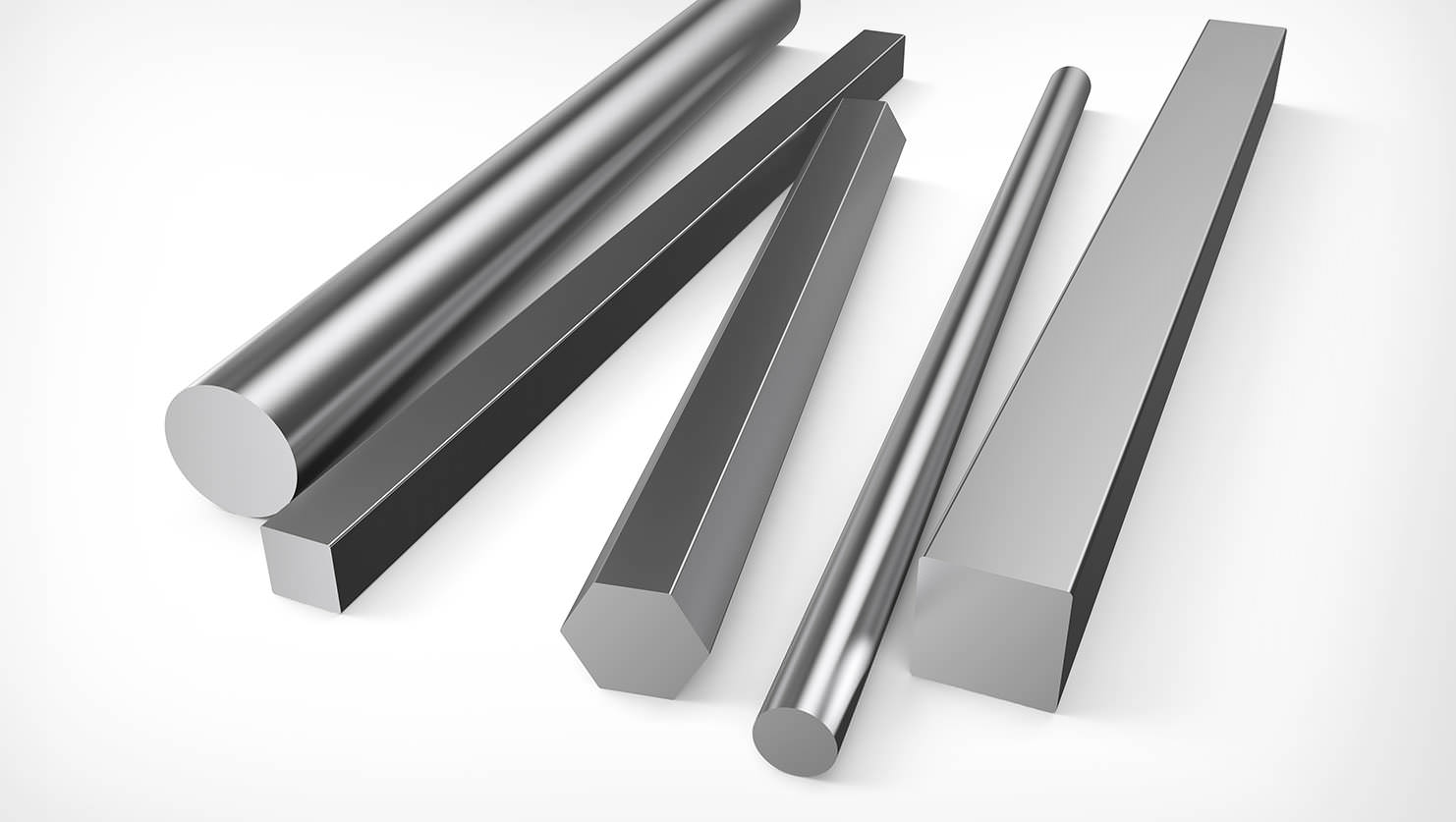

- Shape : Round, Square ,Hexagonal , Flat